- 615-382-8850

- sandrinc@bellsouth.net

- 8:30 to 5:00 (Mon_Fri)

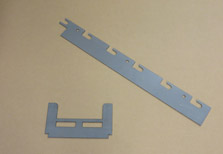

Our Capabilities & Services

High quality products and

services

that we stand behind

About Company

Welcome to S&R, INC.

S&R Inc. was founded in the summer of 1995, as a progressive company specializing in precision cut parts. Since then we have grown and expanded to meet a wide range of services for our customers. Originally, S&R Inc was focused on just laser cutting. However, we now can service our cus...

Projects Portfolio