- 615-382-8850

- sandrinc@bellsouth.net

- 8:30 to 5:00 (Mon_Fri)

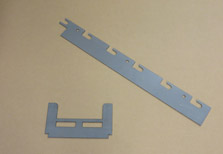

LIGHT FABRICATION SERVICES

| Fabrication Process |

Shearing Rolling 4’ up to 3/16” |

| Equipment |

CNc Back Gauge Large Inventory of Dies |

| Press Capacity | Up to 250 tons |

| Raw Material Forms | Sheet Plate |

| Materials |

Stainless Steel (304 & 316) Aluminum |

| Plastics |

PVC Lexan |

| Other Materials | Composites Rubber Woven Kevlar |

| Finish |

2B Plating |

| Thickness | Up to .5 in |

| Width | Up to 12 ft |

| Depth (Throat) | Up to 1 ft |

| Rolling Thickness | Up to .188 in |

| Rolling Width | Up to 4 ft |

| Weight | Up to 1 ton |

| Tolerance | ± 1° |

| Inspection |

Visual Calipers |

| Quality Control | Process |

| Documentation | Prints Material Certification |

| Additional Services Provided |

Prototype Light Assembly |

| Production Volume | Short and Long Production Runs |

| Typical Lead Times | Less than 2 weeks |

Additional Information

| Industry Focus |

Automotive Automation |

| Intended Applications |

Racks Exterior Trim |

| File Formats | AutoCAD ProNest (Nesting Software) |

Light Fabrication Finishing Options

We offer a diverse range of finishing options for metal components, offering flexibility in enhancing appearance, durability, and performance. These options include electrostatic painting for even coatings, powder coating for durability and corrosion resistance, galvanizing for zinc protection against corrosion, plating for decorative and functional purposes, galvanneal for enhanced corrosion resistance through alloying, and galvalum, a steel coating with aluminum, zinc, and silicon for superior corrosion resistance and heat reflectivity.

The choice of finishing method depends on factors like intended use, aesthetics, and environmental conditions, with each technique contributing to the overall quality and longevity of metal products. Contact us today for more information.