- 615-382-8850

- sandrinc@bellsouth.net

- 8:30 to 5:00 (Mon_Fri)

PRECISION LASER CUTTING SERVICES

| Laser Type | CO2 (Gaseous) |

| Laser Configuration | Flying Optics |

| Cutting Axis | 3-Axis |

| Maximum Output Power | 2500 W |

| Equipment | Ball Screw Motion Systems Shuttle Tables Non-Contact Heads |

| Materials |

Steel Aluminum (Light Gauge) |

| Cutting Thickness | Up to .5 in (Steel) Up to .25 in (Stainless) |

| Cutting Length | Up to 10 ft. |

| Cutting Width | Up to 5 ft. |

| Kerf | .007 to .014 in |

| Accuracy | ± 0.005 in |

| Inspection |

Visual Calipers |

| Quality Control | Process |

| Documentation | Prints Material Certification |

| Additional Services Provided |

Prototype Light Assembly |

| Production Volume | Short and Long Production Runs |

| Typical Lead Times | Less than 2 weeks |

Additional Information

| Industry Focus |

Automotive Automation |

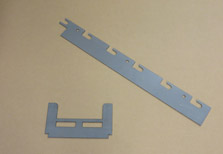

| Intended Applications |

Racks Exterior Trim |

| File Formats | AutoCAD MTC (Nesting Software) Measurement Masters |

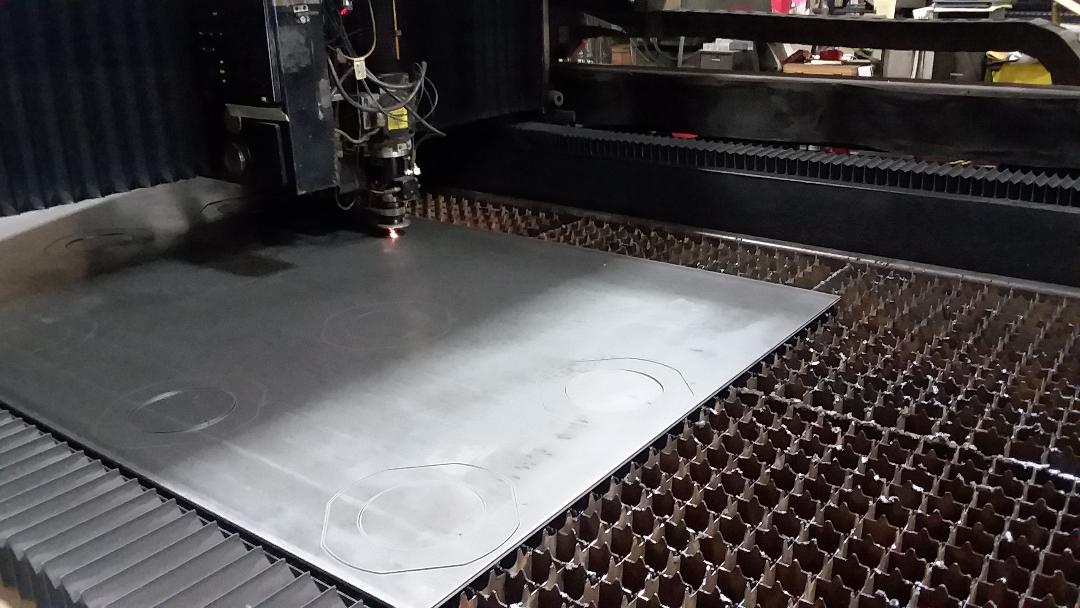

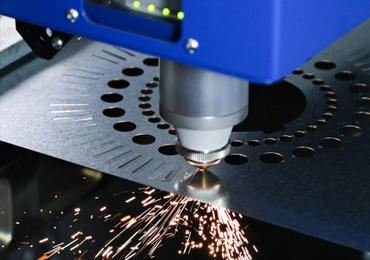

Our Precision Laser Cutting Process

Our precision laser cutting services employ cutting-edge CO2 (Gaseous) lasers in a Flying Optics configuration with 3-axis control, boasting a maximum output power of 2500 W. Equipped with Ball Screw Motion Systems, Shuttle Tables, and Non-Contact Heads, our capabilities extend to steel, stainless steel, aluminum, and tool steel, with cutting thickness up to 0.5 inches (steel) and 0.25 inches (stainless).

With a cutting length of up to 10 feet and width of 5 feet, our precision extends to a kerf of 0.007 to 0.014 inches, ensuring accuracy within ± 0.005 inches. Quality control involves visual inspection, measurement using calipers and pin gauges, and comprehensive process documentation, including material certification.

Beyond laser cutting, our services encompass prototype development, design assistance, tapping, heavy fabrication, light assembly, crating, and packaging. We cater to various industries, such as automotive, military, industrial, construction, automation, touring coaches, and retail, offering solutions for applications ranging from racks and signage to cranes and interior components. Compatible with AutoCAD, MTC (Nesting Software), and Measurement Masters, our production capabilities span short and long runs, with typical lead times of less than two weeks.

Committed to excellence, our precision laser cutting services deliver unparalleled accuracy and efficiency to meet the diverse needs of our clients.